durable

durable LIGHTWEIGHT

LIGHTWEIGHT INEXPENSIVE

INEXPENSIVEOur company, specialising in roofing, has been operating on Polish construction market for not so long now. In 2012, we developed the production process for composite mass used in the production of various construction materials. We started with the production of composite roofing tiles with physical and mechanical properties unmatched by roofing products presently available on the market. Upon completion of tests by the Institute of Construction Technologies (our innovative roofing tiles were outside of existing standards, and therefore subject to comprehensive tests), our plastic roofing tiles were granted Technical Approval B, admitting to use on Polish market of construction products. Although we are presently awaiting the award of CE Certificate, we have successfully completed transactions in Norway, Italy, UK and Belgium. Customers in those markets appreciated the reduction in construction costs and ecological properties of composite roofing tiles. We received EU subsidy for our project and trademark for our products.

We plan to expand our portfolio in the future. We are planning the introduction of terrace boarding, wall cladding, and similar construction products. In 2015, we were awarded multiple medals for our plastic roofing tiles, among others with Gold Medal of Interbud Construction Fair in Lodz, awards of Good Design competition and Expert's Laurels, and this year we were awarded during Tarbud Fair in Wroclaw and Sibex Fair in Sosnowiec. One of the experts justified the selection of our product for Good Design award based on the Opinion presented on the right (Recent events).

As a manufacturer of composite roofing tiles, we keep maintaining the best quality of our products. We adhere strictly to requirements of relevant standards, both national and European, and therefore we are able to guarantee the highest quality of our products.

We offer 50 years of guarantee for our products. Due to composition and the production process used, this period may be further extended. Results of all completed tests and global experience from their use indicate that the lifecycle of roofing made of composite tiles is virtually unlimited. The guarantee period starts running on the date of roofing-tile application.

Due to the expansion of the brand, company TILECO Sp. z o.o. was established in October 2016.

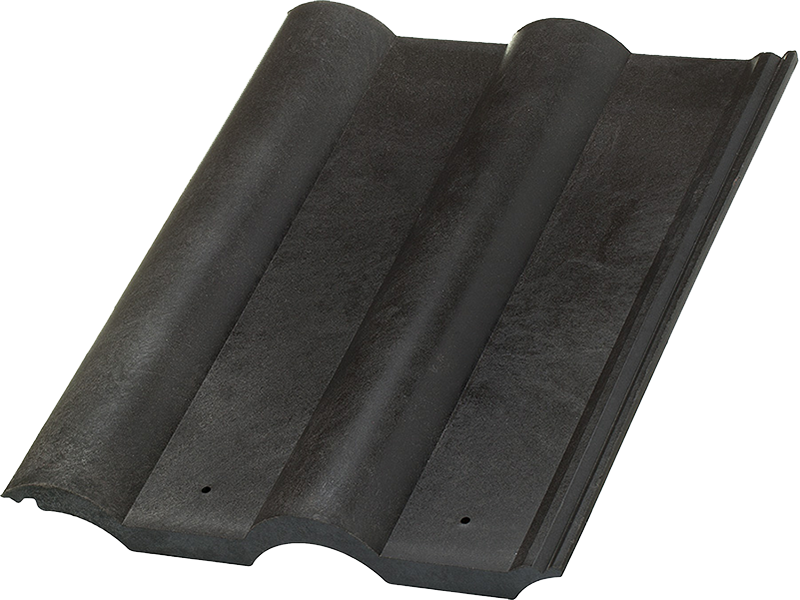

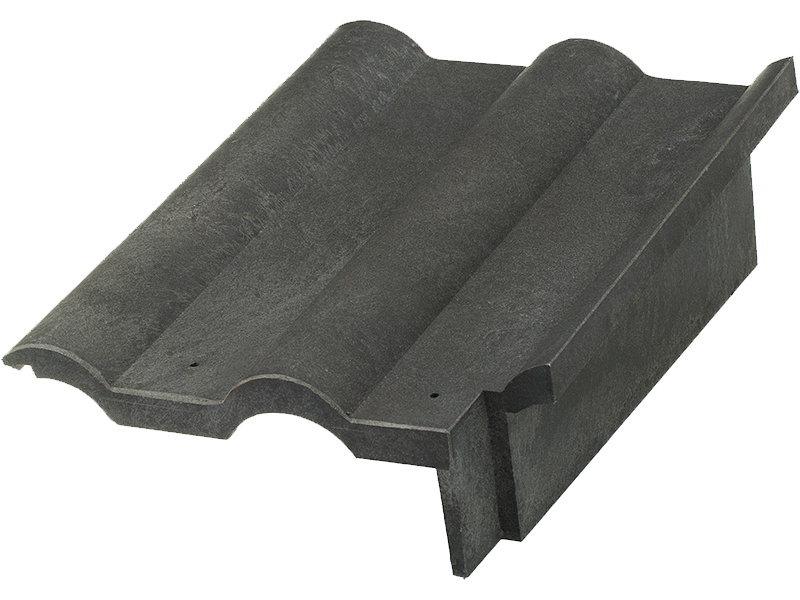

Roofing tile RomaEco is a modern ecological roofing tile made of the composite mass. It has a specific wavy profile - double Roman, producing beautiful and stylish roofing area. Available in three colours: black, red and graphite. Thanks to simple form, it may be applied on both old and new buildings. It is the best match for residential buildings and monumental and historic architecture. Thanks to their properties, composite roofing tiles are also suitable for utility and industrial structures.

Roofing tile weight: 2 kg

Roofing tile dimensions:

Thickness: 10 mm Length: 400 mm

Width: 310 mm

Ridge tile dimensions: Thickness: 10 mm Length: 315 mm

Width: 210 mm Height: 110 mm

Colours: anthracite, graphite, red rustic

Roof surface area: 10 pcs/sqm

Angle of roof inclination: min. 17°

Rafter framing load: 20 kg/sqm

Number of pieces on pallet: 400

Pallet weight: 800 kg

Cost of pallet transport: PLN 159 net

Features that make the product stand out from similar products on the market are:

Utility properties of composite roofing tiles materially differ from properties of other roofing tiles and roofing products on the market, whereas:

- their appearance is no different from ceramic roofing tiles,

- their colour is uniform throughout the profile,

- their surface is smooth (without the need for engobing/glazing),

- they are not susceptible to mechanical damage and they do not break,

- they are 50% lighter than traditional ceramic roofing tiles,

- they feature very low hygroscopic properties,

- no fungi, mould or moss,

- fully frost-proof,

- weather resistance, wind resistant, UV resistant,

- break resistant, they do not crack under the impact of hail or under the load of snow,

- they ensure a better insulation of the attic due to their low thermal conductivity,

- they ensure acoustic insulation, eliminating outside noise produced by rain,

- the low weight of plastic roofing tiles enables using lighter rafter framing and even lighter walls, especially in the case of wooden houses; it is also significant in

- repair works on old roofs,

- replacement of asbestos roofing without reinforcing the rafter framing,

- in transport – a single trailer can hold 1,200 sqm of roofing tiles.

- they are easy to install:

- treatment: you may cut them with any angle grinder or make holes (including for ventilation) at any location without the risk of breaking or cracking,

- attaching to laths: brass, stainless steel or galvanised steel bolts for wood, ensuring wind load resistance,

- no installation waste.

- considering all above advantages, construction of a roof using plastic roofing tiles is cheaper than when using mid-class ceramic roofing tiles, mostly thanks to very low prices of roofing accessories and other savings, such as purchase, transport, installation of materials and lifecycle maintenance of roofs.

- rich colour palette – composite mass for roofing tiles can be dyed to any colour, ensuring a uniform colour of roofing tiles throughout the entire profile.

- environmental aspects - no waste is produced during construction of roof using composite roofing tiles, at any stage, which improves the environmental performance of roofs. It is not without merit that less wood is required for rafter framing to be covered with composite roofing tiles.

- the possibility of replacing the roofing without rebuilding the existing rafter framing,

- the possibility of erecting light roof structures in newly-built buildings/structures,

- composite roofing tiles do not corrode or degrade in contact with ammonia and other aggressive chemicals found in animal droppings or in farming chemicals.

- resistant to the growth of fungi, mould and moss,

- fully frost-proof

- highly resistant to UV radiation;

- the absence of vapour condensation on the inner side of the roof is due to the good insulation properties of composite roofing tiles,

- an alternative to anti-condensation coated roofing tiles.

- not susceptible to mechanical damage and they do not break,

- weather resistant, wind load resistant;

- break resistant, they do not crack under the impact of hail or under a load of snow.

- attaching to laths: brass, stainless steel or galvanised steel bolts for wood, ensuring wind load resistance,

- you may cut them with any angle grinder or make holes (including for ventilation) at any location without the risk of breaking or cracking,

- no need for using systemic components, such as ventilation roofing tiles, aerial roofing tiles, solar roofing tiles, etc.,

- all accessories, such as lighting arresters, aerial masts, solar cells, are bolt-mounted.

Technical Approval

Institute of Construction Technologies

00-611 WARSZAWA | ul. FILTROWA 1 | tel.: (48 22) 825 04 71, (48 22) 825 76 55 | fax: (48 22) 825 52 86

The member of European Union for technical approval in construction (UEAtc), the member of European Organisation for Technical Assessment (EOTA)

9Series: TECHNICAL APPROVALS

TECHNICAL APPROVAL ITB AT-15-9386/2014

Subject to the Decree by Minister of Infrastructure of 8 November 2004 on technical approvals and organisational units authorised to issue such technical approvals (for uniform text see Dz.U. No. 2014, item 1040), in the result of approval procedure by the Institute of Construction Technologies in Warsaw.

it is confirmed that the product as mentioned below is suitable for an application in construction

Composite roofing tiles and ridge tiles

TILECO®

within the scope and subject to principles as specified in this ITB Technical Approval.

Date of validity: 11 September 2019

Warsaw, 11 September 2014

- low weight (20kg/sqm) of roofing tiles enables using a lighter structure of rafter framing, giving savings on construction wood purchase up to 20%; resistance of composite roofing tiles to mechanical damages (ease of treatment at any location without the risk of damage): savings on material costs up to 15%;

- roofing does not require using so-called "system roofing tiles" to install vents and ventilation outlets (openings can be made at any location, using a fret saw): savings in material costs up to 30%;

- attractive pricing of accessories for composite roofing tiles.

- possibility of loading 1,200 sqm (small roof) of roofing tiles on a trailer: savings on transport costs: up to 50%;

- lightweight and easy transport to the roof due to small weight of roofing tiles (ca. 50% saving o labour costs, reduction in duration and cost of roof construction): savings in installation costs ca. 25%.

- unlimited resistance – the roofing tiles may be reused during repair works;

- resistance to growth of moss, fungi and mould: savings on LCC and periodic maintenance of roofs;

- fully frost-proof – the roofing tiles do not crack in frost and therefore do not need to be replaced.

See the video

See the video

RomaEco

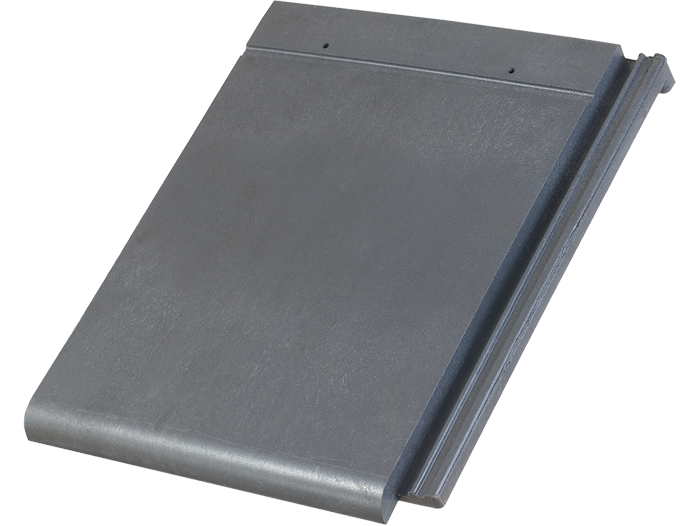

RomaEco  ModernEco

ModernEco

50% LIGHTER

50% LIGHTER  RESISTANCE TO CHEMICALS

RESISTANCE TO CHEMICALS  LOW HYGROSCOPIC PROPERTIES

LOW HYGROSCOPIC PROPERTIES  HIGHLY RESISTANT TO UV RADIATION

HIGHLY RESISTANT TO UV RADIATION LOW DEW POINT

LOW DEW POINT DURABLE

DURABLE EASY IN PROCESSING AND INSTALLATION

EASY IN PROCESSING AND INSTALLATION ACTUAL SAVINGS (MORE THAN PLN 6000)

ACTUAL SAVINGS (MORE THAN PLN 6000) SAVINGS ON TRANSPORT COSTS

SAVINGS ON TRANSPORT COSTS SAVINGS ON LIFECYCLE COSTS

SAVINGS ON LIFECYCLE COSTS

+48 608 380 721

+48 608 380 721 biuro@tileco.pl

biuro@tileco.pl